“There is always a better way.”

— Thomas A. Edison

Manufacturing sterile product has been tough in recent years. From EO environmental, litigation, and capacity risks to uncertainty around gamma supply (coupled with certainty around price increases), many have asked whether there could be a better option for sterilization.

Frustrated with no great commercially-available options, some manufacturers have contemplated building their own in-house sterilization capability. Others have gone so far as to actually construct their own sites.

In this article we suggest some ways manufacturers (contract or OEM) might think about building their own sites or creating alternative arrangements with contract sterilization (CS) provider. Here are the three scenarios we suggest reviewing:

- Optimizing normal commercial terms involves reviewing regional options, reexamining the use of different modalities (e.g. E-Beam instead of gamma), or streamlining / simplifying the process the CS must perform, all in the name of gaining more reliability / better pricing / faster turn times from an existing CS.

- Building a captive facility means constructing your own, captive facility to be used exclusively for your own products.

- Anchoring a new site means partnering with a proven CS (like NextBeam 🙂) by making a longterm commitment about guaranteed spend in exchange for favorable terms.

1. How Would I Go About Optimizing Commercial Terms?

Optimizing to make the required execution process simpler / faster / more flexible should reward the manufacturer with a better price. So, manufacturers might be able to make their specific process at the CS less expensive and easier to execute by doing any mix of the following:

- Optimize packaging – depending on the product, reconfiguring shipper box geometry may net significant savings (especially in E-Beam). We’ve written about this before (here and here).

- Consider removing unnecessary steps / requirements – requirements that involve refrigeration, dry ice treatment, or specific tight times frames can be very costly (expedite fees being some of the worst).

- Consider other regional options – being willing to reexamine shipping lanes or adjust them to access facilities / modalities with lower pricing can often help. See our North American map of all sterilization facilities to help with this. Shipping costs may increase but better flexibility and lower sterilization costs may result.

- Reduce shipment frequency / increase size – CS providers typically have a minimum amount of work to accomplish even on the smallest of jobs (e.g. setup costs, quality assurance costs, etc.) – it’s typically easier to handle fewer large shipments vs. many small ones.

- Reduce required dose or exposure times (e.g. by making the manufacturing process cleaner or loosening the acceptable SAL) – possibly the most difficult of the options presented, as it can require significant amounts of investment in the cleanliness of a manufacturing line and/or a significant amount of revalidation work. However, these investments can pay off over years of repeat CS pricing..

It goes without saying that there are costs associated with most if not all of these that should be evaluated, and that they are very specific to individual product lines and businesses.

2. What Does it Take to Build Your Own E-Beam Facility?

We’ll narrow our commentary here from addressing all modalities to specifically accelerator-based irradiation (e.g. E-Beam and X-ray). There are 2 reasons for this: (a) it’s what we are experts on and (b) it is much more difficult (or not possible) to build new gamma or EO facilities today in North America.

When it can make good sense: low-energy sterilization

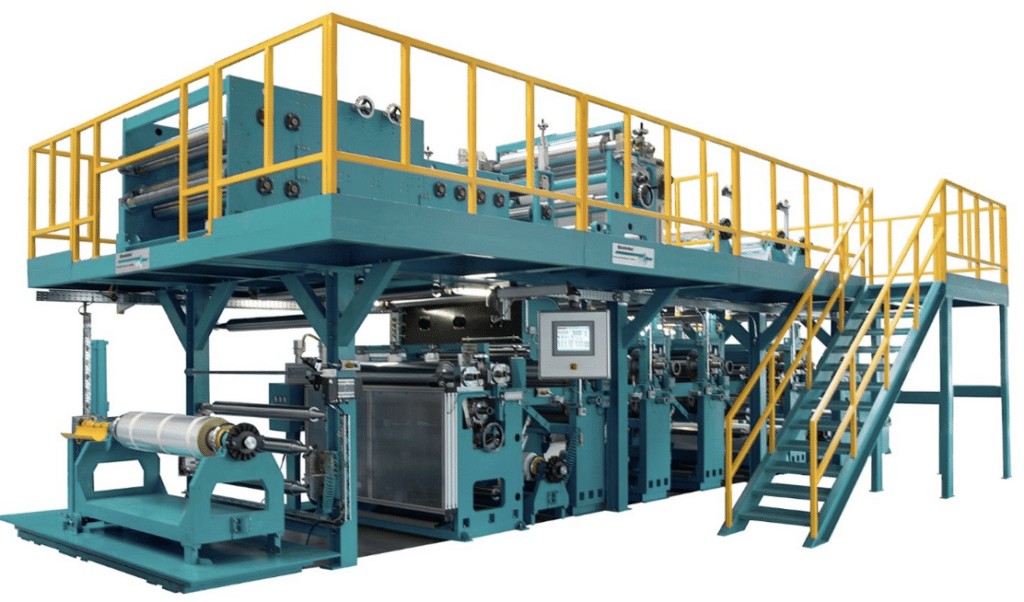

In general we believe that low-energy, in-line E-Beam systems can be especially attractive to manufacturers. Low-energy systems (< 2MeV) and their shielding are typically a fraction of the size of 10MeV E-Beam or X-ray systems. However, their penetration is severely restricted, and thus they are typically only effective at the unit level – and also prior to even intermediate packaging. Bandages on rolls are perhaps the easiest mental model to use, although batch processing of discrete devices is also possible).

The costs and downside risks that should be considered for systems of this type include the cost of custom engineering, installation, and qualification work that will likely be required as well as the level of certainty around the full life of the line itself. Though we are not intimately familiar with these systems, we would estimate order of magnitude pricing is roughly ~$100,000 for very low-rate, batch processing systems up to single-digit $1,000,000s for a low energy but high-power roll-to-roll system capable of extremely high speeds/volumes.

That having been said, we are fans of these arrangements from an efficiency perspective. Sterilizing individual units in high volumes dramatically reduces the amount of energy and system size required. These systems, if thoughtfully constructed and qualified, can be amortized over tremendous volumes of product, producing a strong return on investment over the many years an installed system should be able to reliably operate.

When it makes less sense: very high volumes

With large annual product volumes and high cost products, sterilization costs can be significant. Having large amounts of inventory either in transit to, in treatment at, or returning from a CS at all times can elevate working capital requirements significantly.

When considering E-Beam facilities: we suggest using a minimum capex assumption of $20 million USD for budgetary purposes when considering building a new E-Beam plant. A lead time of at least 24 months should be anticipated. Opex, even at small scale, will involve a highly-trained team. In general the business case breaks down along the following lines:

In our experience, it is difficult to see how annual contract sterilization spend levels (including the cost of transport to-and-from the sterilizer) below $4-5 million per year justify the construction of a new facility (assuming a somewhat geographically convenient CS).

What the above economic analysis does not include is the risk-based issues such as the uncertainty of making longterm plans with a CS: will they have enough capacity to accommodate my business? Will they try to “manage me out” of the facility by raising their prices sharply at their first possible opportunity?

Fundamentally, building a large-scale irradiation facility is difficult to size to a particular and growing business: though the site must be in operation for multiple years to generate a payback, for the majority of its existence it will either be underutilized or at capacity: while irradiation facilities are scalable if built correctly, the large cost of expansion means that a CS is generally better-positioned to optimize costs and offer more favorable pricing.

The below table summarizes risk/cost considerations that should be taken into account when evaluating whether to build a facility for captive use:

| Buy service from contract irradiator | Build irradiation facility | |

|---|---|---|

| Risk |

|

|

| Opex |

|

|

| Capex | Cost of additional inventory |

|

3. Anchoring a New Site

We have watched customers realize the benefits of onsite / nearby facilities with an “anchor customer” model. These customers have high confidence in their ongoing demand / large recurring need for sterilization capacity. They are tired of facing capacity and / or pricing challenges in the open market. But they don’t want to build a facility for several reasons:

- Sterilization is not core to their business model

- They would rather not solely be responsible for the capital and operational costs of the facility (better to reinvest in their core business)

- They don’t have enough capacity to justify a small facility

- They understand that building a sterilization team will require unique expertise that they typically don’t have on staff.

In this case, they can become an “anchor” customer for a new facility, leveraging their long-term demand into a favorable longterm contract for sterilization services with a CS seeking to develop a new facility in their region.

Ultimately this is sort of a “hybrid” approach that can, for the right customer, deliver the best of both worlds: a CS, as a trusted partner, secures a mutually agreeable site, leverages its specific domain expertise to design, construct, and operate a validated facility. The new facility is convenient to the customer and, as an anchor, their demand provides enough revenue to “keep the lights on” while the CS continues to develop the facility and bring in additional revenue over the years after the anchor customer begins using the facility.

The table below outlines how being an anchor customer eliminates or reduces the risks and costs associated with both buying sterilization services on the open market or building your own captive facility.

| Buy service from contract irradiator | Build irradiation facility | |

|---|---|---|

| Risk |

|

|

| Opex |

|

|

| Capex |

|

|

We believe this model makes sense for a great many organizations that have annual spends in the $2-$4M range. Contact NextBeam to better understand what you can expect by becoming an anchor customer for one of our new facilities

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.