Industries We Serve

Want to work with us?

Contact Us

→ Medical Device

→ Laboratory Supply

→ Food & Consumer

→ Packaging

→ Pharmaceutical & Bioprocessing

→ Pet Food & Treat Safety

Take our quiz to understand if you’re a good fit for Electron Beam sterilization →

Packaging Sterilization

Industries We Serve

Want to work with us?

Contact Us

→ Medical Device

→ Laboratory Supply

→ Food & Consumer

→ Packaging

→ Pharmaceutical & Bioprocessing

→ Pet Food & Treat Safety

Take our quiz to understand if you’re a good fit for Electron Beam sterilization →

Packaging Applications

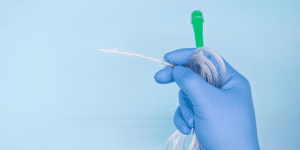

Medical Device Packaging

Protect the sterility of vitally important products with unique requirements – especially those with complex and safety-critical packaging.

Eliminate concern and risk attached to EO residuals and long-lead times for Gamma processing.

Food & Beverage Packaging

Eliminate bacteria, molds, fungi with E-Beam. Safely and effectively treat liners, fitments, pouches, bottle closures, and a wide variety of packaging products.

Cosmetic Packaging

Reduce the bioburden across a variety of packaging materials and form factors: components, applicators, and brushes.

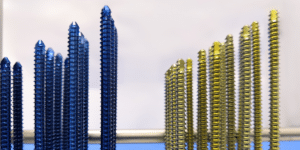

Pharmaceutical & Bioprocess Packaging

Provision packaging for high precision, high-capacity single-use systems that is ultra-clean and ready for large-scale applications.

Other Packaging Applications

Leverage E-Beam as a well-understood and future-proof form of radiation sterilization / bioreduction to help improve supply chain robustness and optionality.

Why Packaging Industry Leaders Are Choosing E-Beam

Quick & Efficient

E-Beam sterilizes packaging in seconds with no residuals, making products safe and ready for distribution. Our $20M facility handles high daily volumes for fast delivery.

Sustainable & Safe

E-Beam uses conventional power and is a greener alternative to Gamma and Ethylene Oxide, without carcinogenic or radioactive materials.

Versatile & Effective

E-Beam works well with common packaging materials and is compatible with Gamma- and EO-qualified products. We offer fast, affordable trials to ensure packaging integrity.

Reliable Results

Our ISO-certified process ensures precise, large-scale sterilization without heat or prolonged radiation, maintaining packaging quality.

Well-Located & Logistically Convenient

NextBeam provides contract sterilization for the following major midwestern metro areas:

📍 Chicago, IL

📍 Minneapolis, MN

📍 Denver, CO

📍 St. Louis, MO

📍 Kansas City, MO

Our central location ensures efficient logistics, rapid turnaround times, and convenient access for businesses of all sizes.

Subscribe to our newsletter to learn about future expansions.

Leverage medical device-grade quality for your business

Our quality system is fully compliant with ISO 13485, ISO 11137, and ISO 9001 for medical device manufacturing, radiation sterilization, and quality management systems.

Let's connect

Complete this form, or email hello@nextbeam.com, and a sterilization expert will get back to you within one business day.

FAQs

- Maintains the integrity and safety of a range of packaging products.

- Helps customers assure that packaging will not introduce contaminants into their production processes.

- Ensures unparalleled quality control by meeting or exceeding rigorous ISO 13485, ISO 11137, and ISO 9001 measures.

- Individual products usually only need a few seconds of precisely calculated irradiation, making processing bulk products and large shipments highly efficient. Once irradiated, products are immediately safe for handling: E-Beam leaves no trace of chemicals or radiation.

- NextBeam’s state-of-the-art facility is designed for high throughput and typically processes product in under 5 days. Expedite options can be made available.