E-Beam vs. Gamma Sterilization

Looking to elevate your sterilization process?

E-Beam delivers unmatched speed and sustainability.

E-Beam and Gamma Side By Side Comparison

| Capabilities | ||

|---|---|---|

| Sterilization Source | Grid electricity | Radioactive material (Co-60) |

| Technology Maturity | High | High |

| Process Quantity | Boxes | Boxes / small pallets |

| Processing Time | Seconds | Hours |

| Sustainability & Environmental Impact | As clean as the electricity used to power the system | Synthetic radioisotopes are required for process |

| Benefits | • Extremely efficient: sustainably process most volume / year • Gentlest on materials as compared to other forms of radiation sterilization • Best $ / capacity available | • Good penetration / tight Dose Uniformity Ratio (DUR) performance • Almost no power required. |

| Limitations | • Product requiring tight DURs can be challenging • Large / dense products can be challenging | • Limited supply of Co-60 radioisotopes • New geopolitical sensitivity in wake of UKR war, China stance |

| Outlook | Growth: efficient, sustainable technology | No growth: isotope supply issues & geopolitical risk |

Advantages

E-Beam

E-Beam offers equivalent-or-better material compatibility, largely due to rapid dose delivery rate.

Depending on requirements, E-Beam systems can process multiple truckloads of product per day. Many medical devices, when packaged to optimize their compatibility with E-Beam, can achieve exceptional throughput and lowest cost to sterilize vs. Gamma.

Once built, E-Beam systems are stable, long-lived, and run on clean grid power – they neither require (e.g. Cobalt-60) nor produce any radioactive material, minimizing their vulnerability to supply chain disruption.

Gamma

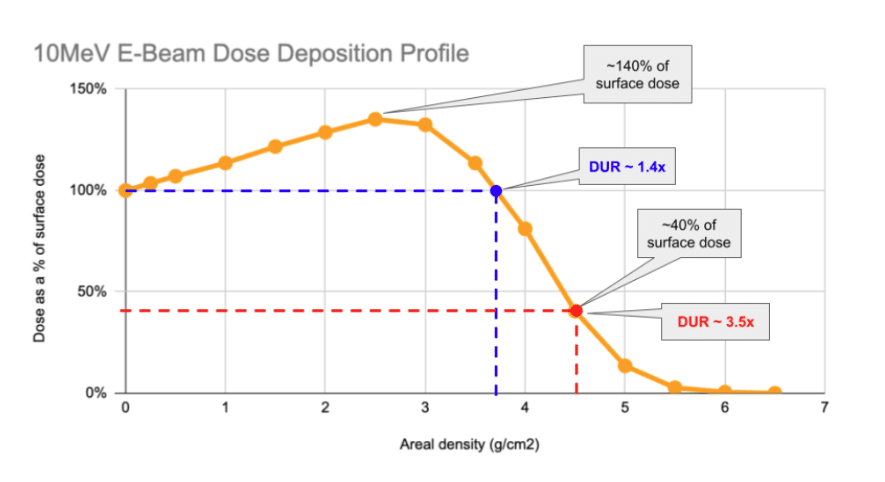

Gamma’s major advantage over E-Beam centers on improved penetration. Gamma radiation has a very flat penetration profile that can be used to penetrate much more mass at once that an E-Beam system can. Gamma radiation is conveyed via photons, which are highly penetrative, while E-Beam radiation is conveyed via high-speed electrons, which are much more massive and accordingly less penetrative.

Due to the flat penetration profile mentioned above, products with very close minimum and maximum dose requirements coupled with challenging physical profiles can work well in Gamma. What’s commonly misunderstood is that, like Gamma, E-Beam can deliver very Low-DUR results, but this is typically dependent on somewhat ideal characteristics of product packaging (e.g. “thin” products without massive density heterogeneity).

What NextBeam Customers Say

“We have now switched to E-Beam for 98% of our products – throughput and turn time have improved dramatically, and quality is great.”

Frequently Asked Questions About E-Beam & Gamma Sterilization

Gamma radiation is highly penetrative but safe when controlled in sterilization facilities. Products don’t become radioactive, and strict safety measures are in place for handling the Cobalt-60 source.

Gamma radiation comes from the decay of Cobalt-60, which emits high-energy photons. These photons penetrate deeply, killing microorganisms by breaking their DNA.

E-Beam works well for many devices, especially with faster processing times. It’s ideal for thinner or less dense products but may require packaging adjustments for optimal results if you’ve used Gamma.

E-Beam is much faster than Gamma, taking seconds or minutes, whereas Gamma can take hours. E-Beam is ideal for high-throughput needs.

A Comprehensive Breakdown Between E-Beam & Gamma

- E-Beam and Gamma sterilize by breaking DNA/RNA bonds, offering similar compatibility across materials.

- E-Beam is faster dosing (seconds), minimizing material degradation like yellowing due to short exposure times.

- Gamma is slower, with dosing that can take hours—best for dense products.

- Both methods can be adjusted based on product density and packaging.

- E-Beam is most effective for low-density products, using dual-pass processing to handle most packaging sizes.

- Gamma offers superior penetration for dense and complex geometries.

- E-Beam is more cost-effective for low-density products, ensuring long-term cost stability.

- Gamma is prone to pricing increases due to cobalt-60 supply constraints, which will likely persist into the future.

- Both E-Beam and Gamma are FDA-recognized as “Established Category A” sterilization technologies, proven and compliant with industry standards.

- E-Beam has experienced significant growth and scalability in recent years, making it an evolving choice for compliance needs.

- E-Beam is powered by electricity, often from renewable sources (e.g., 84% renewable energy at NextBeam’s facility).

- Gamma relies on cobalt-60, which presents sustainability challenges due to radioactive material and limited supply.

- E-Beam is scalable and able to handle higher throughput with advanced technology.

- Gamma is limited by the availability of cobalt-60, with no new US facilities expected in the coming decade.