Selecting a sterilization modality and approach is an important aspect of delivering sterile medical devices. Further, third-party sterilizers are most commonly selected to deliver this final, critical-to-quality service. So, how should a medical device manufacturer select a sterilization provider?

We assembled the following key question areas to help inform your decision.

Capabilities: Assure the provider has the capabilities that you need

- What modalities do you offer (e.g. E-Beam, Gamma, EO?)

- What is your available capacity for product like mine?

- What is your standard turnaround time for shipments? Are expedite options available?

- What in-house lab capabilities do you have, if any?

- Where are your facilities located?

- Do you offer specialty capabilities (e.g. refrigerated / frozen storage, arranging shipping, etc.)

Pricing Model: Assure that you understand how pricing is determined and could change over the lifetime of your product

- What is your pricing structure for validation activities (e.g. dose mapping, specific dosing, dose audits, etc.)

- Please explain how you set pricing for production processing.

- What is your pricing surcharge for expedited processing?

- Once my product is validated, what fees would be charged for a standard production run?

Quality: Understand the provider’s quality system and history

- Are you audited to the ISO 13485 quality standard for the manufacturing of medical devices for the standard of the modality that you are using (e.g. 11135, 11137)?

- Are you registered with the FDA or any other regulatory bodies (e.g. Japan’s Pharmaceuticals and Medical Devices Agency (PMDA) or the European Commission’s MDR (Medical Device Regulation)

- What is your availability to host an audit?

- What is your scrap rate?

- Please outline your business continuity plan.

- Is your quality system paper or digital? How are certificates of processing delivered?

Service: Understand how the provider assures an excellent customer experience

- Please summarize your customer feedback over the past year.

- How do you support your customers day-to-day? Is there a dedicated point of contact for ongoing support?

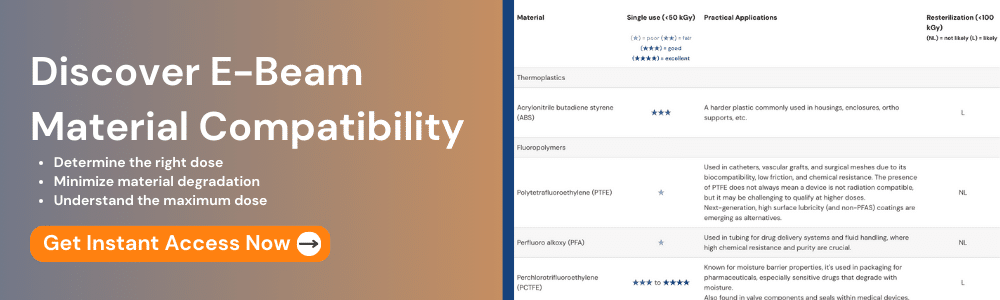

- Do you offer consultation services during the design and material selection stages to ensure sterilization compatibility and help us understand / optimize the process?

- Have you been subject to any litigation around the sustainability of the facility we would use?

Selecting the right sterilization provider can be a complex decision. Explore our sterilization facility map to find a partner near you, or contact our team for precise, efficient, and reliable E-Beam irradiation services.

Good luck and happy hunting!

The NextBeam Team

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.

The Environmental Protection Agency (EPA) has recently issued revised guidelines regarding the use of ethylene oxide (EtO) in sterilization processes. These changes are part of a broader initiative to...

The FDA recently issued guidance requiring cat and dog food manufacturers to incorporate Highly Pathogenic Avian Influenza (HPAI) considerations into their food safety plans (“Cat and...

Despite the FDA, USDA, and other regulatory agencies having long endorsed the safety of irradiated foods, we periodically hear about skepticism of these endorsements in the marketplace. With that in...