Best-of-breed irradiation services tailored to your needs.

Volume Irradiation Applications

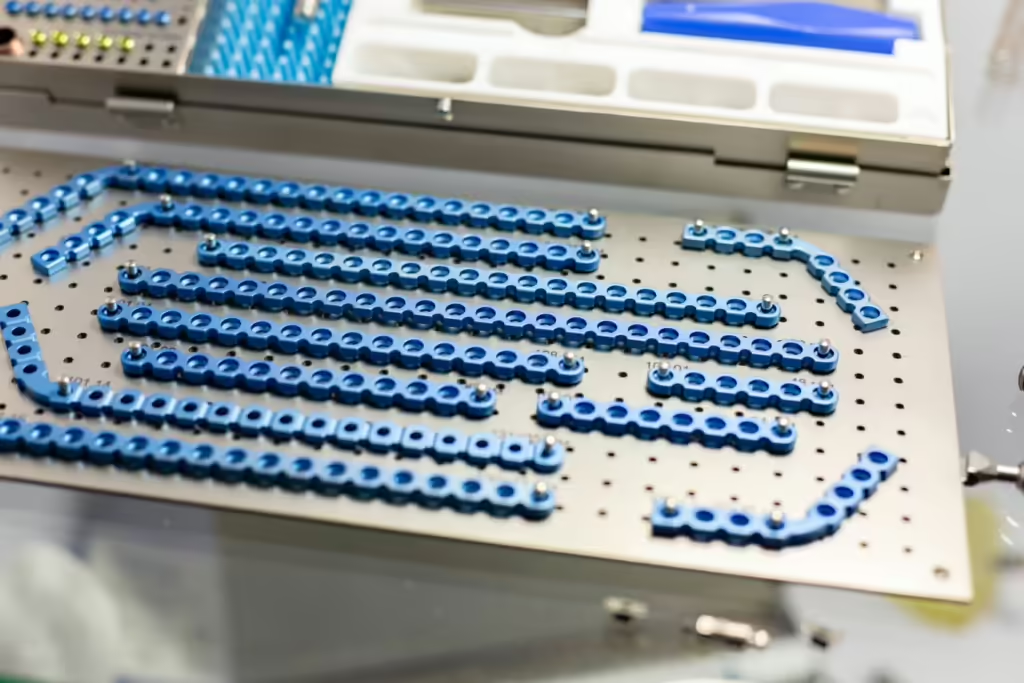

Electron Beam Sterilization

Minimize contamination and maximize product safety with reliable, efficient, and sustainable electron beam sterilization.

We process volumes ranging from a fraction of a pallet to multiple full truckloads of product.

Want to learn more about E-Beam? Explore our Knowledge Center.

Materials Modification

We support customers that use radiation for:

- Crosslinking: Improve strength and heat resistance.

- Chain Scission: Achieve precise control over material properties.

- Composite Curing: Ensure superior composite integrity.

- Semiconductor Applications: Enhance performance of critical components.

We help enhance your materials’ performance, durability, and functionality, giving you a competitive edge.

Validation, Testing, & Small Batch Processing

Dose

Mapping

- Perform uniform sterilization by mapping radiation dose across your product for new and existing products.

- Rapid turnaround - in most cases complete within 5 days of protocol approval.

- Collaborative approach to understanding product nuances for optimal results.

Specific

Dosing

- Tailored dosing to meet your requirements.

- Services include single-batch irradiation for clinical trials or releases.

- Conduct maximum dosing studies for packaging or material integrity.

Standard Method Validations

- Fully managed and irradiation-only studies available.

- Qualification studies include VDmax validation and ISO 11137 Method 1 validation.

Small Batch Processing

- Process small batches to meet specific client requirements.

- Example applications include clinical trial/single batch release and max dose study for packaging/material integrity.

Feasibility Studies

Know if E-Beam will work on your product within 2 weeks.

Send us a small sample of your product, and we’ll examine material compatibility, performance benefits, and potential outcomes and provide you with summary analysis and recommendations for next steps as applicable.

What We Cover:

- Material Compatibility: Assess potential impacts on physical and chemical properties.

- Performance Enhancement: Identify how e-beam can improve product durability and functionality.

- Outcome Prediction: Evaluate sterility assurance and overall effectiveness.

Need to know today? Try our e-beam compatibility calculator.

We Set (& Meet) High Standards

Facility built from the ground up for medical device standards: ISO 11137, ISO 13485, 21 CFR Part 820

Rapid turnaround times - in most cases we qualify product within 5 business days

Cloud-based 21 CFR Part 11-compliant document control system for anywhere/anytime record retrieval

Well-Located & Logistically Convenient

NextBeam provides contract sterilization for the following major midwestern metro areas:

📍 Chicago, IL

📍 Minneapolis, MN

📍 Denver, CO

📍 St. Louis, MO

📍 Kansas City, MO

Our central location ensures efficient logistics, rapid turnaround times, and convenient access for businesses of all sizes.

Subscribe to our newsletter to learn about future expansions.

Let's Connect

Complete this form, or email hello@nextbeam.com, and a sterilization expert will get back to you within one business day.

FAQs

How much volume can you process?

Our process is designed to support a wide range of volumes, from a single pallet to multiple truckloads of product.

What is the maximum product size you can process?

The maximum standard product envelope is 50” x 30” x 48”. If you have larger needs, please contact us for further assistance.

What industries do you serve?

We serve a diverse range of industries, including medical devices, lab animal science, laboratory supply, and more.

Quality Without Compromise

All of our processes meet the highest-grade industry benchmarks for quality, designed from the ground up to adhere to ISO 13485, ISO 11137, and ISO 9001 standards for medical device manufacturing, radiation sterilization, and quality management systems.