Industries We Serve

Want to work with us?

Contact Us

→ Medical Device

→ Laboratory Supply

→ Food & Consumer

→ Packaging

→ Pharmaceutical & Bioprocessing

→ Pet Food & Treat Safety

Take our quiz to understand if you’re a good fit for Electron Beam sterilization →

Pet Food & Treat Safety

Elevate product safety and quality with Electron Beam treatment, delivering a critical kill step for premium pet food and treats.

Industries We Serve

Want to work with us?

Contact Us

→ Medical Device

→ Laboratory Supply

→ Food & Consumer

→ Packaging

→ Pharmaceutical & Bioprocessing

→ Pet Food & Treat Safety

Take our quiz to understand if you’re a good fit for Electron Beam sterilization →

Pet Food Applications

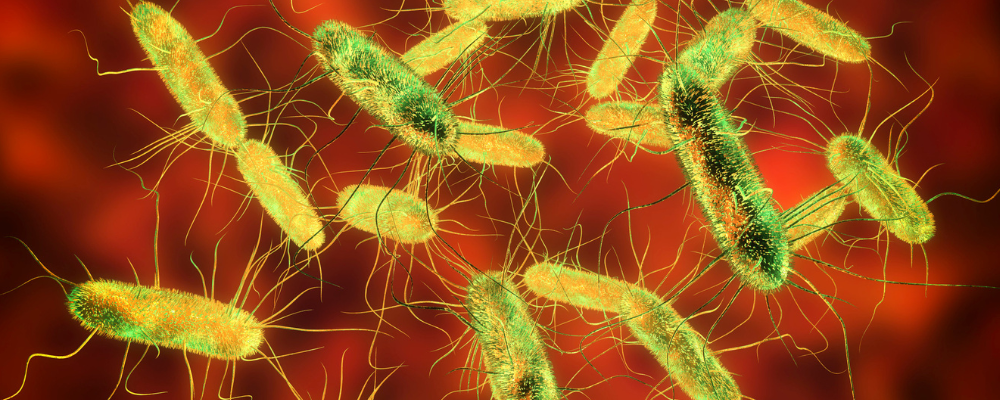

Pathogen Reduction

Achieve at least a five-log microbial reduction, effectively targeting pathogens like Salmonella and E. coli, to ensure pet food and treats are safe for pets and their owners.

Nutrient Preservation

Safeguard the nutritional value of high-end pet foods while eliminating harmful bacteria, keeping pets healthy without compromising the quality of their food.

Extended Shelf Life

Extend shelf life and prevent spoilage by reducing microbial contaminants, ensuring premium pet food and treats stay fresh and safe.

Packaging Integrity

Process pet food and treats in their final packaging to eliminate contamination risks, ensuring products remain safe, sealed, and ready for use.

Why Pet Food Industry Leaders Are Choosing E-Beam

Quick & Efficient

E-Beam sterilizes products in seconds with no residuals, making products safe and ready for distribution. Our $20M facility handles high daily volumes for fast delivery.

Sustainable & Safe

E-Beam uses green electricity and is a sustainable alternative to Gamma and Ethylene Oxide, without carcinogenic or radioactive materials.

Versatile & Effective

Achieve broad-spectrum microbial control, effectively reducing pathogens and contaminants in critical pet food products.

Reliable Results

Our ISO-certified process ensures precise, large-scale sterilization without heat or prolonged radiation, maintaining product quality.

Well-Located & Logistically Convenient

NextBeam provides contract sterilization for the following major midwestern metro areas:

📍 Chicago, IL

📍 Minneapolis, MN

📍 Denver, CO

📍 St. Louis, MO

📍 Kansas City, MO

Our central location ensures efficient logistics, rapid turnaround times, and convenient access for businesses of all sizes.

Subscribe to our newsletter to learn about future expansions.

Leverage medical device-grade quality for your business

Our quality system is fully compliant with ISO 13485, ISO 11137, and ISO 9001 for medical device manufacturing, radiation sterilization, and quality management systems.

Let's connect

Complete this form, or email hello@nextbeam.com, and a sterilization expert will get back to you within one business day.

FAQs

The short answer is–yes!

The long answer is that many raw materials and final products are suitable for E-Beam processing, but some aren’t.

Speak with one of our qualification specialists today. Answer a few questions, and we can start validating your products in our state-of-the-art dosimetry lab. From there, we’ll develop a customized bioreduction plan for your needs and even help you optimize your product and packaging for irradiation.

- Processing speed and flexibility

- Meets rigorous quality standards for bioreduction

- Little to no adverse effects on product quality or material characteristics

Regulatory agencies dictate what can and cannot be irradiated. We comply with industry standards for irradiation, quality management systems, and medical devices outlined in ISO 13485, ISO 11137, and ISO 9001.