Premium raw pet foods are ascendant in the marketplace. According to Business Research Insights, In 2021, the global pet raw food market was valued at approximately USD 2.47 billion. It is projected to reach about USD 8.72 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 12.17% during the forecast period.

Decades of > 10%/y growth are rare feats for sizable industries indeed. But the growth in premium raw is being driven by the shifting role of pets: owners increasingly view their pets as family members, leading to higher spending on premium and natural pet food products. This higher spend is inline with trends in human food: health-conscious consumers believe that raw, “as nature intended” diets are generally healthier.

However, the FDA is not as sanguine about the true nature of raw pet food. While dogs are generally well-equipped to eat raw food, it can be highly dangerous or even lethal to humans when contaminated with salmonella, listeria monocytogenes, and other pathogens. Having an effective “kill step” is critical to manufacturing safe product.

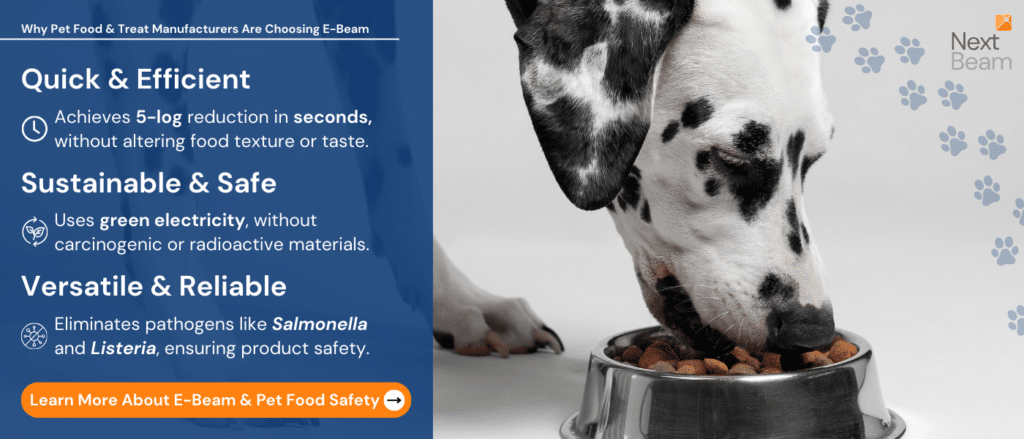

E-Beam is gaining market traction in the space for multiple reasons over other microbial inactivation technologies:

- Products retain superior smell and taste: radiation allows use of foil or other non-vented packaging that limits loss or oxidation of volatile organic scent and flavoring compounds (this is the reason why coffee and many human snack foods use foil pouches). High pressure or steam processes must use vented packaging that is not compatible with non-vented packaging.

- E-Beam simplifies the product supply chain and reduces risk: irradiation can be performed after final packaging, eliminating risk of reintroducing contamination after the microbial inactivation step, and reducing complexity of supply chain between manufacturing and distribution

- Irradiation can be cost-competitive: while irradiation is often more expensive per pound compared to high pressure / steam technologies, for top shelf dry foods and high value snacks (especially low water content products), E-Beam is both highly cost competitive and most effective in reducing risk.

At NextBeam, our facility is registered with FDA and USDA APHIS, with accreditations for ISO 13485, ISO 9001, and MedAccred.

We irradiate medical devices, pharmaceuticals, tissue/biologics, laboratory supplies, specialty polymers, and many other product types.

Contact us today for a no-obligation consultation on your specific product needs.

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.