The U.S. Food and Drug Administration (FDA) is increasingly scrutinizing the use of per- and polyfluoroalkyl substances (PFAS) in consumer products due to their potential health and environmental impacts.

Often referred to as “forever chemicals” due to their persistence in the environment, PFAS are a class of synthetic compounds widely used for their resistance to heat, water, and chemical degradation.

While much attention has been given to PFAS in food packaging and cosmetics, upcoming FDA restrictions could significantly impact medical device manufacturers, many of whom rely on PFAS-based materials for their unique performance properties.

The Role of PFAS in Medical Devices

PFAS are integral to the medical device industry due to their versatility and reliability in critical applications. Key uses include:

- Catheters and Guidewires: Polytetrafluoroethylene (PTFE), a type of PFAS, is commonly used for its low-friction properties, enabling smoother navigation of devices within the body.

- Coatings and Barriers: PFAS are used to create hydrophobic coatings, prevent microbial contamination, and enhance durability.

- Implants and Surgical Tools: Certain PFAS materials are chosen for their biocompatibility, chemical inertness, and resistance to degradation in the body.

- Tubing and Seals: PFAS elastomers ensure high chemical resistance and flexibility in medical-grade tubing, seals, and gaskets.

These applications demonstrate how PFAS have become essential for meeting strict medical device performance standards, particularly in high-stakes environments where failure is not an option.

Potential FDA Restrictions on PFAS

The FDA, alongside other regulatory bodies such as the Environmental Protection Agency (EPA), has been advancing efforts to address PFAS contamination and exposure.

Possible actions include:

- Bans on Specific PFAS: Restrictions may target individual PFAS compounds with proven health risks, such as certain long-chain varieties linked to cancer, hormonal disruption, and liver damage.

- Usage Limits: The FDA may impose limits on PFAS concentrations in specific medical device applications.

- Labeling Requirements: Manufacturers may be required to disclose PFAS content in their devices, aligning with growing transparency demands.

- Enhanced Testing Protocols: The FDA could mandate additional testing to ensure PFAS leachability and exposure levels remain within safe limits during a device’s lifecycle.

These measures reflect the FDA’s broader mandate to ensure public safety while balancing the need for innovative medical solutions.

Challenges for Medical Device Manufacturers

For medical device manufacturers, the potential restrictions present several challenges:

Material Reformulation

Many medical devices rely on PFAS due to their unmatched properties. Finding alternative materials that meet performance, biocompatibility, and regulatory standards is a daunting task. Developing and validating replacements could require significant time and investment.

Regulatory Compliance

Adhering to evolving regulations requires proactive measures to assess current PFAS use, demonstrate compliance, and implement risk mitigation strategies. Manufacturers may need to conduct additional testing, which can strain resources and delay product launches.

Product Redesign

Replacing PFAS materials may necessitate substantial design changes, requiring revalidation of safety and efficacy. This could affect device performance, regulatory approvals, and market competitiveness.

Litigation Risks

As awareness of PFAS-related risks grows, manufacturers could face lawsuits over legacy products containing PFAS. Ensuring robust documentation and proactive risk management will be critical.

Opportunities for Innovation

While the challenges are significant, potential PFAS restrictions also create opportunities for innovation:

Development of PFAS-Free Alternatives

Manufacturers have an opportunity to lead the market by developing high-performance materials that eliminate or reduce PFAS content. Advances in nanotechnology, biopolymers, and other material sciences could yield viable substitutes. At NextBeam we are already aware of surface coatings and other key device components being reengineering with PFAS-free materials.

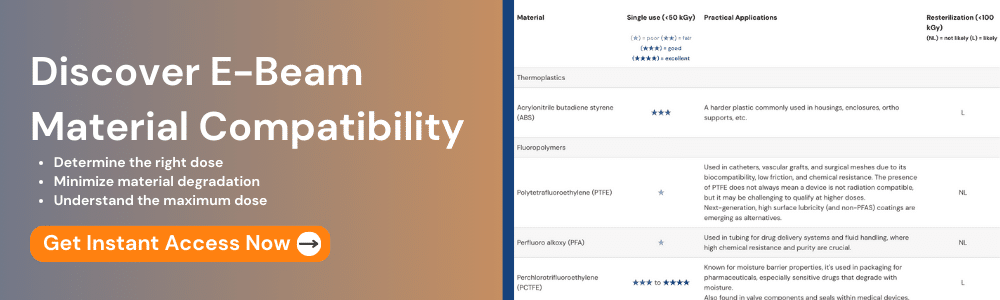

Improved Sterilization Compatibility

Many PFAS-free materials are compatible with advanced sterilization methods like electron beam (E-beam) and X-ray sterilization. The move to PFAS-free will most likely accelerate the transition away from requiring EO for many (not all, but many) devices.

Sustainability as a Differentiator

Adopting sustainable materials and manufacturing processes can differentiate companies in a competitive market increasingly focused on environmental responsibility.

Preparing for the Future

To navigate potential FDA PFAS restrictions, medical device manufacturers should take proactive steps:

- Understand Exposure: Assess PFAS use across product lines to identify at-risk materials and prioritize alternatives.

- Invest in Research and Development: Allocate resources for material innovation and validation to stay ahead of regulatory changes.

- Engage with Regulators: Participate in public comment periods, industry associations, and working groups to advocate for balanced policies.

- Educate Stakeholders: Ensure internal teams, customers, and partners understand the implications of PFAS restrictions, the company’s response strategy, and opportunities for innovation and benefit.

Conclusion

The FDA’s potential PFAS restrictions mark a turning point for the medical device industry, pushing manufacturers to balance regulatory compliance, product performance, and sustainability. While the road ahead may be complex, it is also an opportunity to innovate and adapt to changing market and societal expectations. Companies that act decisively—embracing alternatives, investing in sustainable solutions, and engaging with regulators—will be well-positioned to thrive in a new era of medical device manufacturing.

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.