The FDA recently issued guidance requiring cat and dog food manufacturers to incorporate Highly Pathogenic Avian Influenza (HPAI) considerations into their food safety plans (“Cat and Dog Food Manufacturers Required to Consider H5N1 in Food Safety Plans”).

This directive emphasizes the importance of mitigating the risks associated with H5N1 contamination, not only to ensure food safety but also to protect public health and trade. While traditional heat or chemical sterilization methods are effective, they often degrade product quality—a problem that electron beam (e-beam) sterilization solves efficiently.

The FDA’s Focus on Food Safety

According to the FDA, HPAI represents a significant hazard that must be addressed in hazard analysis and critical control points (HACCP) strategies for pet food manufacturing. As noted in the FDA’s guidance, contamination risks during processing or ingredient sourcing pose threats not just to animals but also to humans who may handle these products.

How E-Beam Technology Meets the FDA’s Safety Mandate

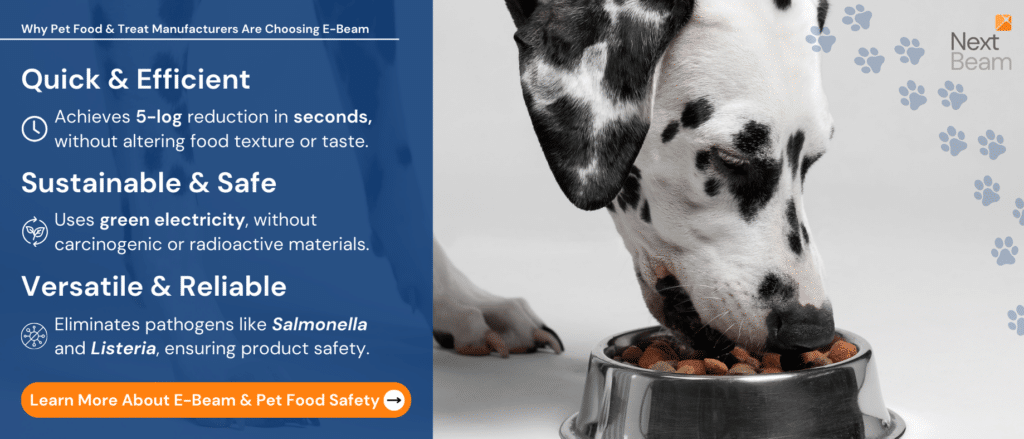

E-beam sterilization is a non-thermal, chemical-free method that delivers effective pathogen inactivation while preserving product integrity. Depending on the product, e-beam technology can achieve up to a 5-log reduction in microbial load with a modest dose of just 8 kGy. This includes inactivation of viruses like avian influenza, providing a cutting-edge solution for compliance with FDA requirements.

Key benefits include:

- Precision Pathogen Control: E-beam technology delivers consistent microbial reduction without damaging the sensory or nutritional quality of pet food.

- Alignment with FDA Guidance: By incorporating e-beam sterilization, manufacturers can proactively meet the FDA’s heightened food safety expectations for products potentially exposed to HPAI risks.

- Sustainability: Eliminates the need for chemical sterilants, making it an environmentally friendly option.

What This Means for Pet Food Manufacturers

As the FDA continues to heighten its scrutiny on food safety protocols, especially for pet food products containing poultry ingredients, the adoption of e-beam technology offers a forward-looking solution. In addition to ensuring compliance, this advanced sterilization technique protects supply chains, maintains product quality, and strengthens consumer confidence in the safety of pet food.

At NextBeam, we specialize in helping pet food manufacturers adapt to regulatory changes with scalable e-beam solutions that enhance food safety without compromising product quality. Ready to take the next step in safeguarding your operations? Let’s talk about how we can help you meet the FDA’s evolving requirements while staying ahead of the competition. Book a 1:1 with a sterilization expert today.

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.