Why we say E-Beam is the perfect food safety treatment for premium raw freeze-dried pet food

The ever-innovative pet food industry has witnessed a surge in demand for freeze-dried raw products as pet owners seek to provide their animals with diets that mimic natural feeding behaviors.

However, the raw nature of these products introduces major safety challenges, particularly regarding the elimination of pathogens like Salmonella, Listeria, and E. coli. Among the available technologies, electron beam irradiation (E-Beam) and high-pressure processing (HPP) are two widely recognized methods for pathogen reduction in raw pet food.

While both are effective in improving food safety, E-Beam irradiation stands out as the superior technology, particularly for freeze-dried raw pet food, due to its precision, efficiency, and minimal impact on product quality.

Overview of E-Beam Technology

E-Beam irradiation is a cold pasteurization technique that uses a high-energy electron beam to eliminate pathogens in food. The electrons disrupt the DNA of pathogens, rendering them inactive without the use of heat, chemicals, or water. This makes E-Beam irradiation a highly effective solution for pathogen control, especially in raw and minimally processed foods.

Key advantages of E-Beam for freeze-dried raw pet food include:

- Non-thermal processing: E-Beam does not raise the temperature of the product, preserving the texture, flavor, and nutrient profile of freeze-dried foods.

- Rapid treatment: The process is quick, often completed in seconds, making it suitable for high-volume production lines.

- True end-of-line kill: E-Beam can process product at the very end of the production process, often in its final packaging.

- Minimal environmental impact: E-Beam generates no waste products, uses no water, and has a smaller carbon footprint compared to many other food safety technologies.

Overview of HPP Technology

87,000 psi, to inactivate pathogens. The product is submerged in water within a pressure chamber, and the pressure is uniformly applied to destroy microorganisms.

While HPP has gained traction in the pet food market, it presents challenges when applied to freeze-dried raw pet food:

- Moisture dependency: HPP relies on water as the pressure medium, making it incompatible with dry products like freeze-dried raw pet food unless rehydrated, which compromises the product’s intended state.

- Extended processing time: The cycle time for HPP, a batch process, can last several minutes, slowing down production.

- Potential for texture changes: The high pressure can alter the texture and structure of foods, particularly those that are delicate or highly porous, such as freeze-dried items.

- Higher operational costs: HPP systems require significant energy and water, adding to production expenses and environmental concerns.

Comparing E-Beam and HPP for Freeze-Dried Raw Pet Food

1. Compatibility with Freeze-Dried Foods

- E-Beam: Ideal for freeze-dried products as it works directly on dry or low-moisture items without requiring rehydration. It preserves the lightweight, porous structure characteristic of freeze-dried foods.

- HPP: Inherently moisture-dependent, HPP cannot process freeze-dried raw pet food without first reintroducing moisture, which defeats the purpose of freeze-drying and compromises product integrity. Thus, a HPP process can only be run prior to freeze-drying, leaving the potential for subsequent food contamination and risk later in the production and packaging process.

2. Effectiveness in Pathogen Reduction

- E-Beam: Delivers consistent and reliable pathogen reduction, with precise dosage control ensuring safety without overexposure.

- HPP: Effective for inactivating pathogens, but its performance is less consistent in products with varying densities or moisture levels.

3. Impact on Nutritional and Sensory Quality

- E-Beam: Leaves proteins, vitamins, and other sensitive nutrients intact, maintaining the natural qualities of raw food. It also preserves the flavor and aroma that appeal to pets.

- HPP: Can cause changes in protein structure, nutrient bioavailability, and texture.

4. Efficiency and Scalability

- E-Beam: Processes products in seconds, making it highly scalable for large-scale production. Its compact systems integrate seamlessly into existing production lines.

- HPP: Longer cycle times and batch processing limit throughput, making it less efficient for high-volume operations.

5. Environmental Considerations

- E-Beam: A dry, chemical-free process with low energy requirements and no water usage, aligning with sustainability goals.

- HPP: Consumes significant water and energy, contributing to higher operational costs and a larger environmental footprint.

Time, Money, Risk — Advantage: E-Beam

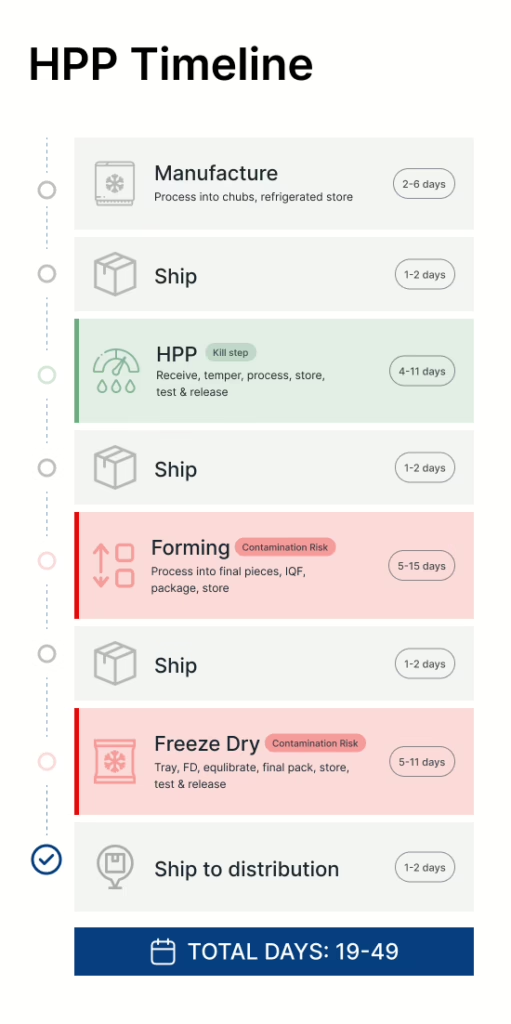

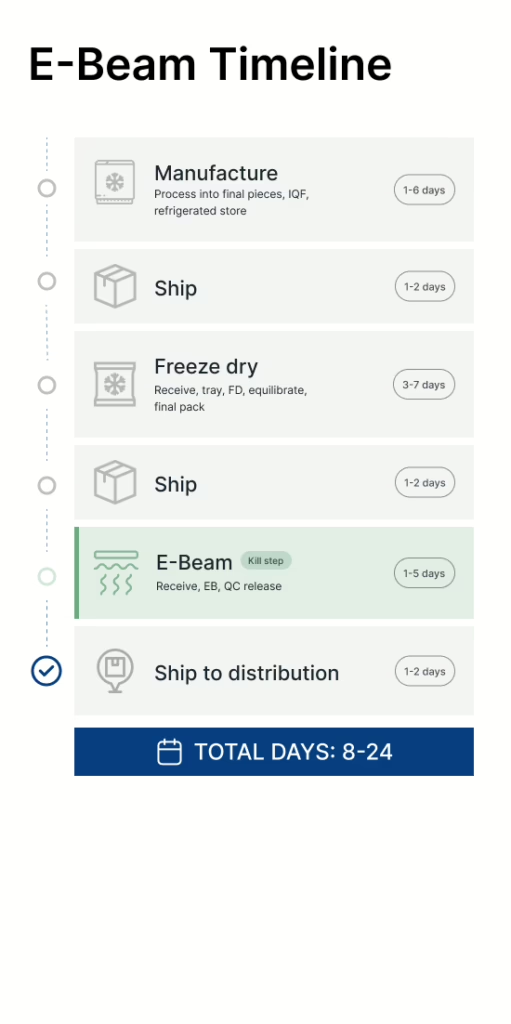

Manufacturing raw freeze-dried pet food at scale is a complex process fraught with opportunity for food contamination and safety risk.

E-Beam is especially well-suited for freeze-dried raw pet food primarily because of its strong penetrative qualities: E-Beam can process product at the very end of the manufacturing process, post freeze-dry, in its final packaging. This key advantage dramatically virtually eliminates risk of contamination, as compared to HPP, where major processing must be done post-kill step.

While best-in-class risk reduction is the primary reason to use E-Beam, it also dramatically accelerates the production timeline for premium freeze-dried raw pet food, cutting production times nearly in half. The below timeline illustrates the manufacturing processes for both processes.

Cost can vary widely depending on the nature of the product itself and its manufacturing volumes. However, broadly speaking, E-Beam is typically very cost-competitive with HPP on a lb-of-finished product basis.

E-Beam: The Future of Freeze-Dried Raw Pet Food Safety

Given its compatibility with dry products, precision, and ability to maintain product quality, E-Beam irradiation is the clear choice for freeze-dried raw pet food manufacturers seeking a cutting-edge food safety solution. It not only ensures robust pathogen control, accelerated time to market, and competitive economics, but it also supports the industry’s sustainability goals by reducing water and energy usage.

Additionally, E-Beam’s rapid processing and scalability align with the growing demand for raw pet food, enabling manufacturers to meet market needs efficiently while delivering safe, high-quality products.

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.