We founded NextBeam to serve the medical device industry – a sector that is intense and demanding when it comes to quality and microbial cleanliness. But what we’ve learned since we activated our $20M state-of-the-art facility is that our modern and sustainable electron beam technology can offer massive benefits for users from other industries as well.

More Than Medical Products

Electron Beam (E-Beam) irradiation has diverse applications in various industries, from food and cosmetics to packaging and pharmaceuticals. Shipments are processed quickly under high standards using E-Beam.

Consumers want to have confidence that the raw ingredients in their products are safe. Laboratories need assurance that their devices are free of contaminants. Manufacturers want products shipped in their terminal packaging without disruption or degradation.

Mold mitigation, sterilization, and bioburden reduction are all achievable with E-Beam.

Product Quality, Shelf-Life, and Safety

E-Beam can meet your product needs. Whether your product is a single-use pipette or make-up, E-Beam effectively achieves sterility or microbial load reduction of products in their final packaging.

Terminal sterilization immediately prior to distribution means fewer opportunities for re-contamination before a product lands in the hands of consumers.

Irradiation disrupts microbial growth through two primary mechanisms:

- The irradiation can directly cause cell death by destroying vital parts of the microorganisms or viral DNA. This breakdown prevents replication or reproduction.

- E-Beam also indirectly causes a secondary chemical reaction that results in the death of microbes.

E-Beam effectively eliminates E. coli in blueberries while maintaining quality, nutritional value, and shelf-life. Other foodborne illnesses, like Salmonella and Tulane virus, are reduced or inactivated.

Irradiation can also decontaminate packaging materials. In food and other industries, microbes on a container can lead to spoilage and lost revenue before they even hit the shelves. Even low E-Beam doses can reduce bioburden levels when paired with an antimicrobial film.

Reducing the bioburden of a product and its packaging helps combat microbial growth, preventing spoilage. Irradiation of specific packaging materials can even result in beneficial property changes.

Reducing the bioburden of a product and its packaging helps combat microbial growth, preventing spoilage. Irradiation of specific packaging materials can even result in beneficial property changes.

How E-Beam Stacks Up to EO and Gamma

Electron beam irradiation is an under-utilized treatment method that offers several of advantages over other preservation techniques and systems.

E-Beam requires only a fraction of processing time compared to Gamma irradiation or the use of Ethylene Oxide (EO). E-Beam’s use of grid electricity rather than hard-to-source and highly-radioactive materials or toxic industrial chemicals makes it more environmentally friendly and a reliable resource for growing industry needs.

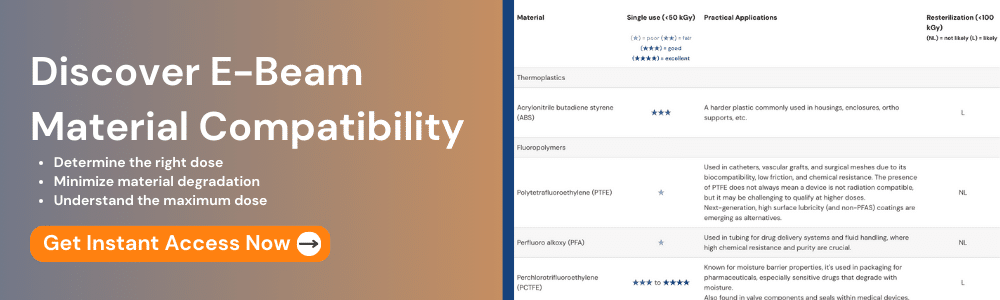

E-Beam can treat a wide array of products, features fewer material compatibility issues, and is less likely to result in material degradation.

Other preservation methods, like steam, autoclaving, and freezing, can negatively impact product quality. E-Beam typically produces minimal heat and will extend shelf-life without materially altering a product’s characteristics.

Dispelling E-Beam Myths and Misconceptions

E-Beam is a safe and highly controlled sterilization technique. It does not require dangerous chemicals or radioactive agents.

It leaves behind no trace residuals on products or packaging.

The treatment of each product is unique, and each item undergoes a detailed qualification process to verify that E-Beam processing can successfully treat the product.

Qualified E-Beam products fully penetrate all items in a sealed package. There is little to no material damage or product degradation on qualified items. There are virtually no changes to the sensory or nutritional qualities of food or other consumables.

Get Clean with NextBeam

At NextBeam, we can apply medical device-grade sterilization processes and technology to a wide range of products from other industries: food, cosmetics, pharmaceuticals, packaging, nutraceuticals, and others.

We’ll develop a customized bioreduction or sterilization plan based on your specific product and requirements during the qualification process.

From consumables to packaging materials, we’ll help you optimize your product for high-volume processing and sterilization in our state-of-the-art facility. And we’ll do it quickly: we can qualify products in less than a week.

Our skilled team is waiting to hear from you. Connect with us to request a custom product analysis from one of our sterilization experts. We also welcome all questions, feedback, and opportunities for collaboration.

Additional Articles We Think You Might Like

Have a question? Speak with a sterilization expert today, at your own convenience.