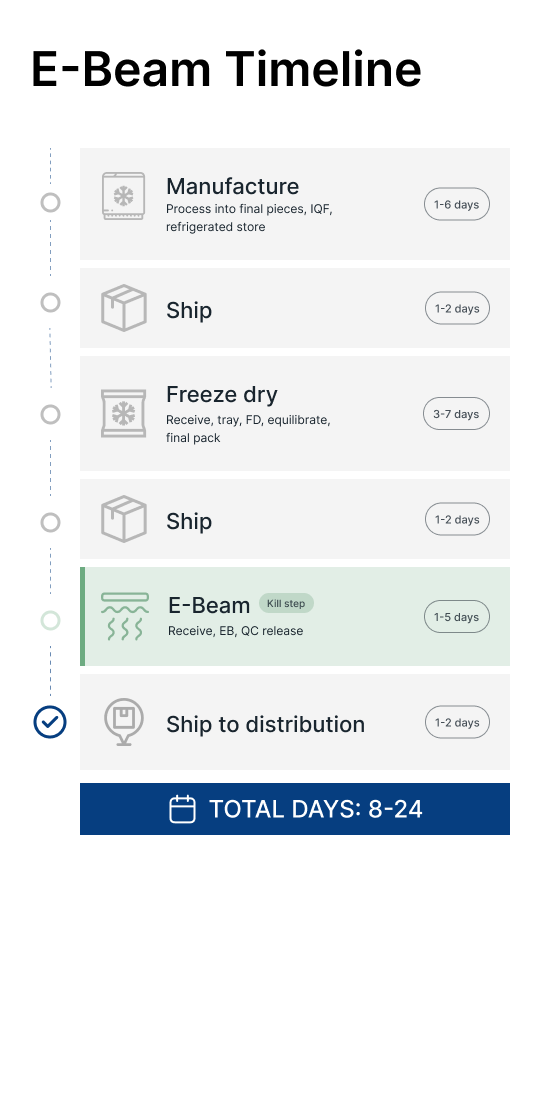

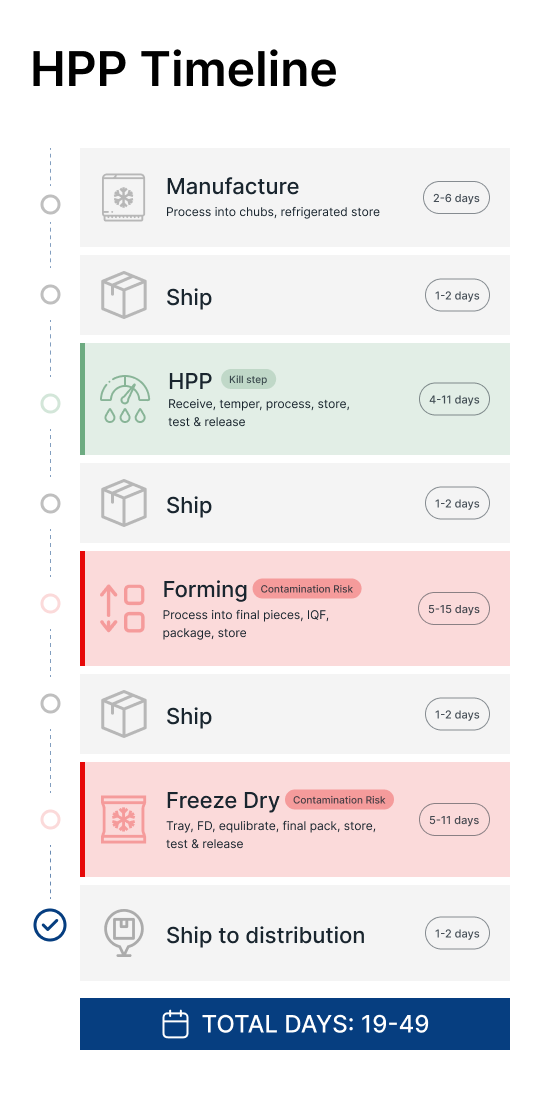

E-Beam vs. High-Pressure Processing (HPP) Microbial Control

Ready to upgrade your kill step?

E-Beam delivers unmatched speed and sustainability.

E-Beam and HPP Bioreduction Side by Side Comparison

| Capabilities | ||

|---|---|---|

| Source | Grid electricity | Grid electricity |

| Technology Maturity | High | High |

| Process Quantity | Boxes | Boxes (flexible packaging only) |

| Processing Time | Seconds | Minutes |

| Sustainability & Environmental Impact | As clean as the electricity used to power the system | As clean as the electricity used to power the system |

| Benefits | • Extremely efficient: sustainably process most volume / year • Gentlest on materials as compared to other forms of radiation sterilization • Best $ / capacity available Efficient with low Aw/moisture products | • Retains freshness, flavor, and nutrients • Suitable for high-moisture products • Works well for food products with very high water (texture can change) suitable for high Aw products (>0.92) |

| Limitations | • Product requiring tight DURs can be challenging • Large / dense products can be challenging | • High operational costs and limited packaging compatibility • Slower throughput compared to E-Beam • Does not work well with low water content (e.g. freeze-dried) foods |

| Outlook | Growth: efficient, sustainable technology | Niche adoption in fresh food and pet food markets |

Advantages

E-Beam

E-Beam sterilization is a non-thermal process, making it ideal for products sensitive to heat or moisture, such as freeze-dried pet food, packaged foods, By sterilizing without raising the temperature, E-Beam preserves the structural, functional, and sensory qualities of products. This ensures food retains its texture, flavor, and nutrient profile

E-Beam is compatible with a wide range of materials, including polymers, composites, and rigid packaging, while minimizing the risk of material degradation. This versatility supports diverse applications across industries like healthcare, food safety, and industrial manufacturing, making it a reliable choice for products requiring precise treatment.

E-Beam systems are powered by clean grid electricity, generate no waste by-products, and require no water, offering a significantly lower carbon footprint compared to many alternative methods. Its sustainability makes it a future-ready solution for industries seeking to minimize their environmental impact without compromising efficiency.

E-Beam’s rapid processing delivers sterilization doses in seconds, making it ideal for high-volume production lines. Unlike batch-based methods, it operates continuously and without interruptions, enabling manufacturers to meet market demands efficiently. True end-of-line capability allows E-Beam to sterilize products in their final packaging, streamlining operations and reducing handling steps for maximum throughput.

HPP

HPP excels in treating high moisture content foods. Delicate items like fruit purees, plant-based beverages, and refrigerated dips maintain their texture and quality while achieving extended shelf life.

HPP significantly extends the shelf life of fresh, high-moisture foods by reducing spoilage and inactivating spoilage organisms. This makes it an effective solution for products like fresh juices, dips, and ready-to-eat meals, ensuring freshness while minimizing food waste

HPP’s batch-based process allows manufacturers to carefully monitor and control each production run, making it well-suited for small to medium-scale operations. This precision is particularly advantageous for artisanal or premium products that require close attention to quality and consistency.

What NextBeam Customers Say

“Do we have a customer who has switched from HPP to E-Beam? If so, can we ask for a testimonial? If not, we could use this quote from the FDA and change the section title a bit to something like:”

What Experts Say

“Irradiation does not make foods radioactive, compromise nutritional quality, or noticeably change the taste, texture, or appearance of food. In fact, any changes made by irradiation are so minimal that it is not easy to tell if a food has been irradiated.”

Frequently Asked Questions About E-Beam & HPP Microbial Reduction

HPP (High Pressure Processing) uses extreme pressure to inactivate pathogens, making it ideal for high-moisture foods like juices, dips, and fresh pet food . E-Beam uses radiation to reduce microbial presence quickly and effectively, making it better suited for dry goods, medical devices, and products in rigid or sealed packaging.

No, E-Beam is a non-thermal process that reduces microbial activity without raising the temperature of food. It preserves the structural, sensory, and nutritional qualities of food products, similar to HPP, while also maintaining packaging integrity.

While it targets DNA and microorganisms, enzymes are generally unaffected by the ionizing radiation levels used in E-Beam processing. This makes E-Beam a strong option when enzyme activity needs to remain intact.

E-Beam is significantly faster, completing the process in seconds as a continuous process. HPP, by contrast, operates in batch cycles and typically takes several minutes per batch, making it better suited for smaller-scale operations.

HPP is best suited for high-moisture products such as fresh juices, guacamole, ready-to-eat meals, and raw pet food. E-Beam is ideal for dry, packaged goods, medical devices, pharmaceuticals, and freeze-dried pet food.

HPP works with flexible, water-resistant packaging like vacuum-sealed plastic but is not compatible with rigid materials such as glass or hard plastic. E-Beam is compatible with a wide range of packaging, including rigid plastics, composites, and sealed items, without compromising integrity.

Both methods are FDA- and USDA-approved for food safety.

A Comprehensive Breakdown Between E-Beam & HPP

- E-Beam: Compatible with a wide range of materials, including rigid plastics, composites, and sealed packaging. Short exposure times reduce material degradation.

- HPP: Requires flexible, water-resistant packaging (e.g., vacuum-sealed plastic). Not compatible with rigid materials like glass or hard plastics.

- E-Beam: Highly effective for reducing I presence in dry and packaged products. Can inactivate bacteria (Salmonella, Listeria monocytogenes, E. coli) and spores in seconds.

- HPP: Effective for high-moisture foods, targeting similar pathogens (Salmonella, Listeria, E. coli). However, it does not inactivate bacterial spores, such as Clostridium botulinum, making it unsuitable for products requiring complete microbial inactivation.

- E-Beam: Cost-effective for large-scale operations due to high throughput and continuous processing. Lower per-unit costs for high-volume production.

- HPP: Typically more expensive because of batch processing, equipment costs, and long cycle times.

- E-Beam: Widely recognized by regulatory bodies (e.g., FDA, USDA) for microbial reduction in food and medical devices. Accepted globally for high-volume industrial use.

- HPP: Approved by FDA and USDA for food safety. Commonly used where minimal processing is prioritized.

- E-Beam: Powered by clean grid electricity, uses no water, and produces no waste by-products. Offers a smaller carbon footprint compared to traditional microbial reduction methods.

- HPP: Relies on and energy use, which can contribute to higher environmental impact. Effective for clean-label products despite resource requirements.

- E-Beam: Highly scalable, capable of processing truckloads of products daily.

- HPP: Scalability requires large investments in multiple HPP processing machines which may limit the ability of toll processors.